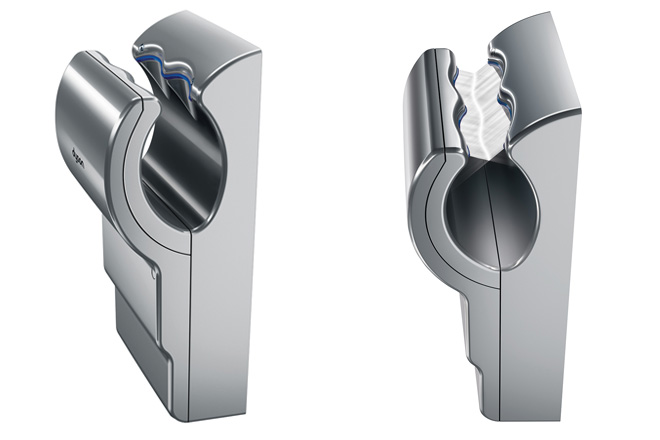

In response to customer feedback, Dyson engineers have re-engineered the apertures of the Dyson Airblade hand dryer to reduce noise. The Airblade uses jets of air that travel at 430mph, which create air turbulence when they collide – resulting in a loud sound.

In the Dyson Airblade dB model, two sheets of high-velocity unheated air travel through 0.4mm scallop-shaped apertures, quickly scraping water from hands like a windscreen wiper – leaving them fully dry. The scallop design increases the distance travelled by the two sheets of air before they collide. An overhanging lip on the front aperture alters the angle of the air exiting the machine, further reducing the sound made when the sheets collide.

The result is a hand dryer that is 50% quieter than its predecessor, with no compromise on performance – it dries hands in only 10 seconds. James Dyson explains: “Powerful machines create noise. Others might decelerate their motor, reducing airflow – and therefore performance – to make machines they claim to be quiet. But by focusing on acoustic engineering, Dyson engineers ensured that Airblade is still the fastest hand dryer, but with reduced volume.”

A team of 25 specialist acousticians at Dyson work to reduce vibrations, hone airflow and change the motor’s tone to engineer machines that are quieter and have better sound quality, while maintaining high performance. £1.5m is spent every year researching noise-cancelling technologies and designing specialised acoustic components.

The Helmholtz silencer eliminates specific motor tones. It is made of six chambers, each with a hole on the outside. Once the air exits the motor it passes over the openings of the silencer. The internal cavities create tones at the same frequency as, but of a different phase to, the motor tone. These chambers isolate and substantially reduce the first and fourth harmonic of the motor tone – the unpleasant frequencies most prominent to the human ear.

The Dyson digital motor V4 is a power-dense brushless DC motor that utilises a bonded neodymium magnet encased in a carbon fibre sleeve. It is small, powerful and capable of creating 430mph sheets of air that dry hands quickly and efficiently. It is one of the world’s smallest and fully integrated 1600W motors. Using digital pulse technology, it accelerates from 0-90,000rpm in less than 0.7 seconds.

There are currently 295 patents and patents pending on Dyson Airblade hand dryers using Airblade technology. The Dyson digital motor V4 has 190 patents and patents pending.